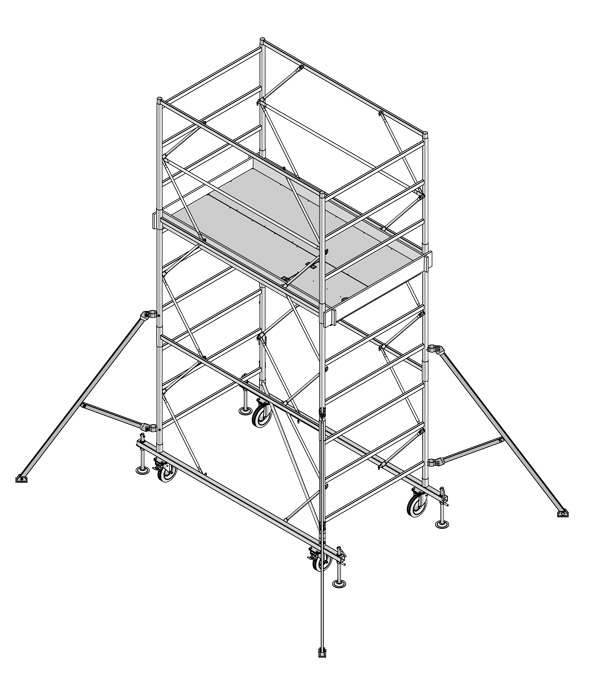

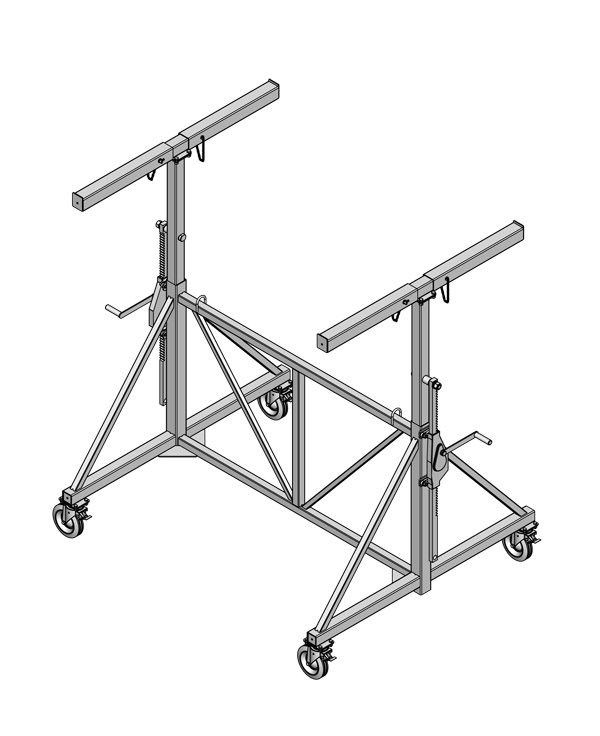

Formwork tables VARITABLE

Description

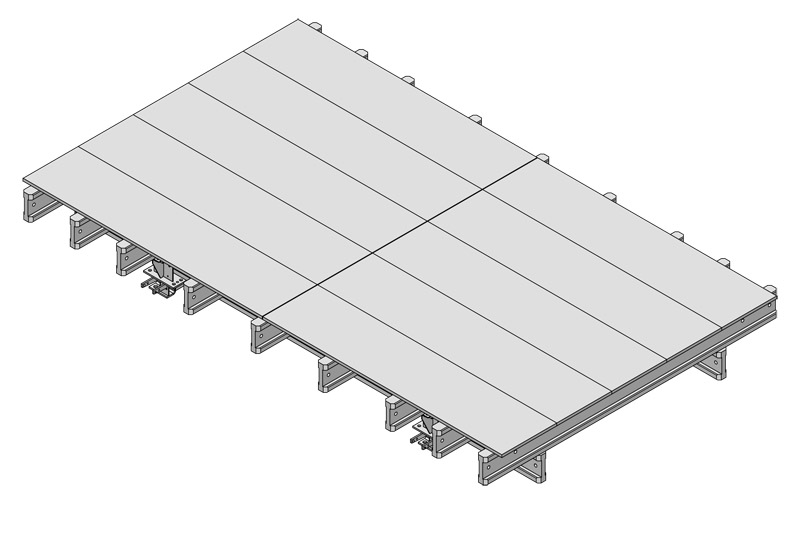

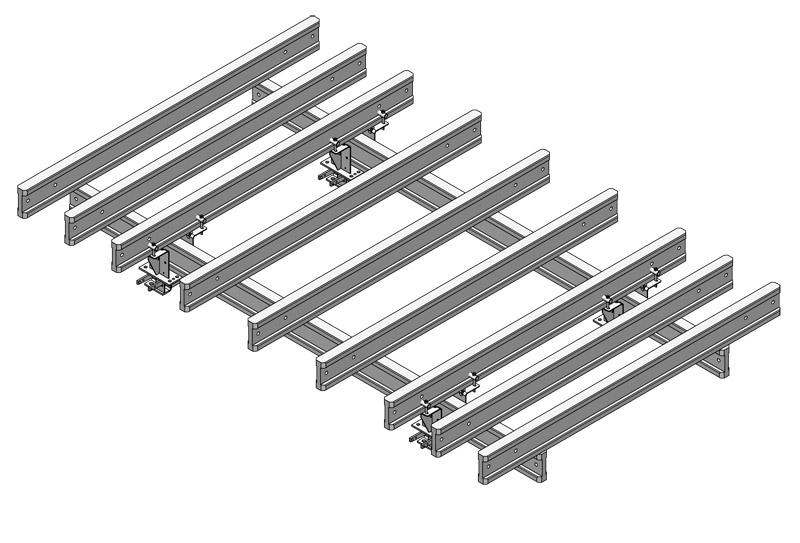

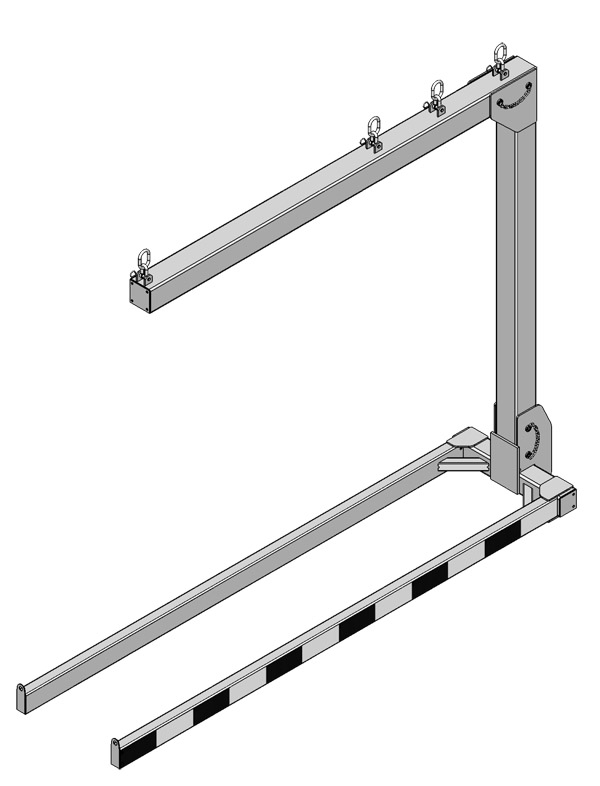

VARITABLE by Variant is a fast and efficient way of forming large-area slabs. The system can be easily adjusted to varying structural and architectural designs (loads, shapes, concrete surface etc.) Once assembled, a complete table unit can be positioned, adjusted, stripped and repositioned to a new area of concrete placement minimal labor. The table can be shifted along the slab using Variant’s shifting trolley. In order to gain maximum efficiency, Varitable can be easily combined with VARITABLE PLUS and VARIFLEX systems.

Load-bearing capacity:

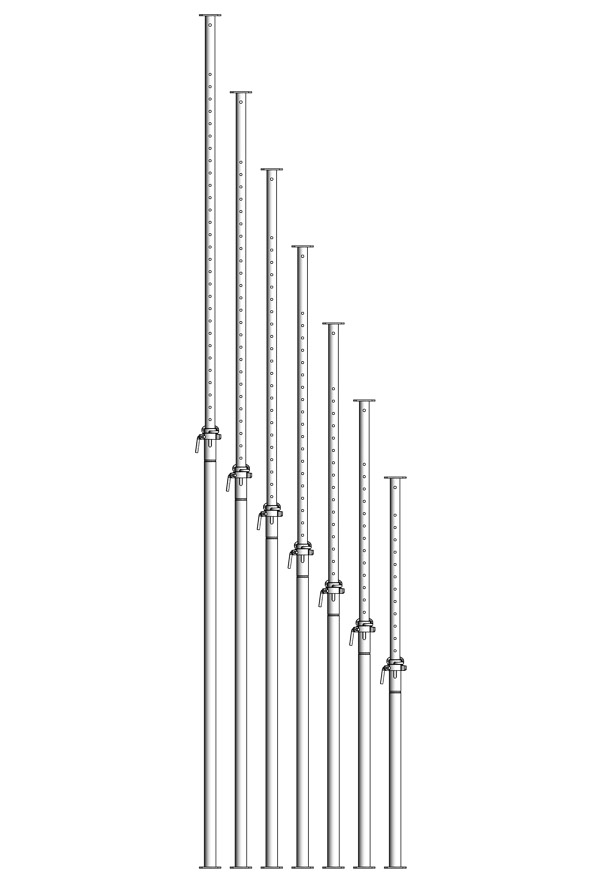

- Due to its load-bearing flexibility, VARITABLE system can be adapted to bear loads of fresh concrete of different kinds of slab thicknesses. Optimal and cost-effective use within a range of slab thicknesses up to 500 mm.

- Maximum table form height—6.0 m.

Cost-effective:

- Due to complete repositioning of the units, the time and labor is cut short.

- Table form can be horizontally repositioned without using crane.

- Fewer parts speed up assembly.

- High durability resulting in lower the expense.

- Reduction of expenses by means of system adaptability.

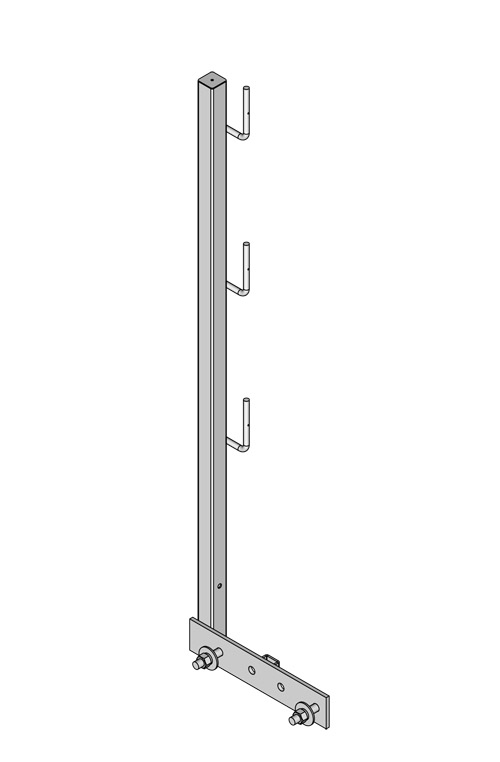

- Galvanized or powder coated props, for long service life.

System adaptability:

- Can easily be combined with VARITABLE PLUS and VARIFLEX systems.

- Any type of form-facing can be selected

Easy handling and planning:

- Any requirements in architectural design of flat concrete slabs can be met.

- Can cover a wide area of practical applications.

Safe use:

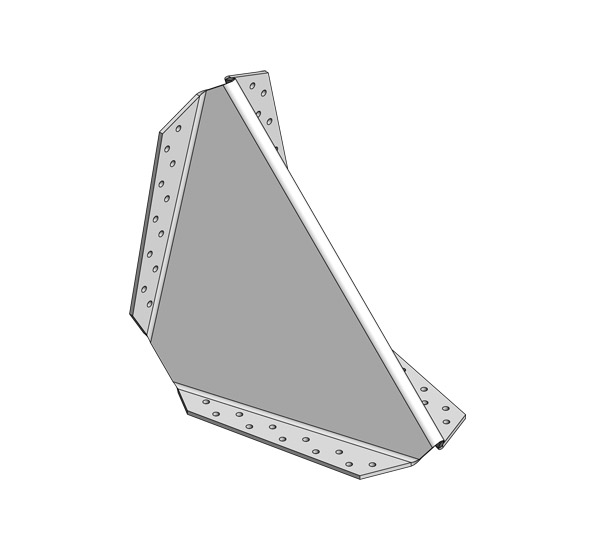

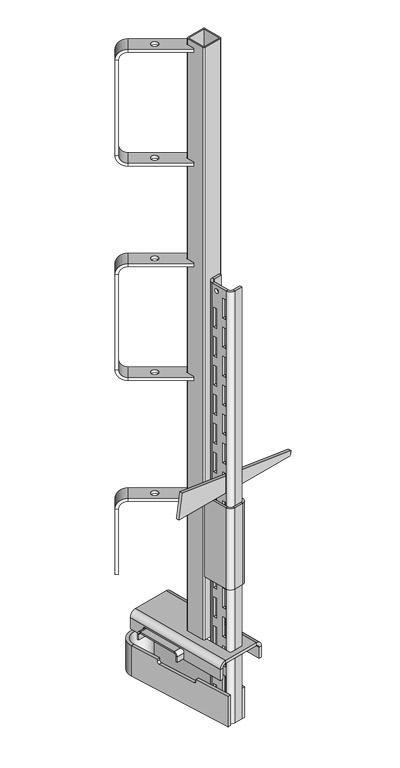

- Accessories such as — working platforms makes for save and easier handling of the system.

- Safe working already during assembly.

Main features of the system:

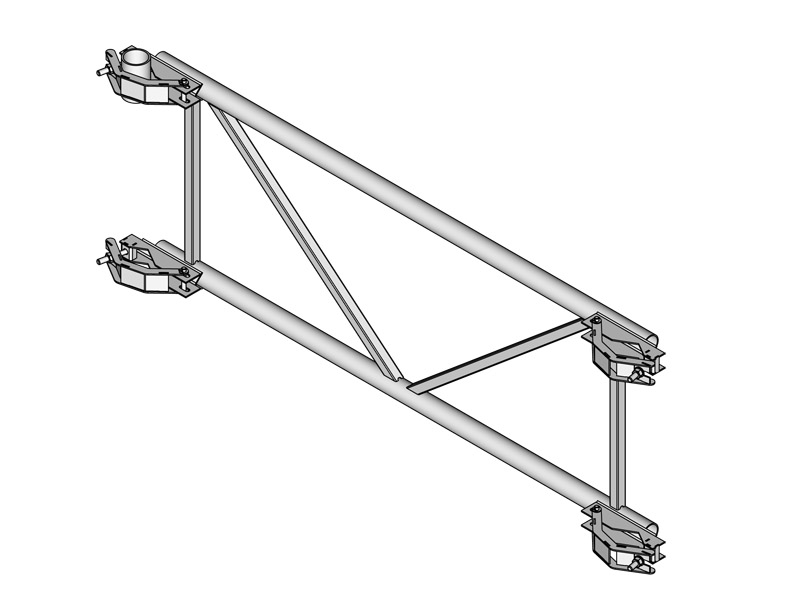

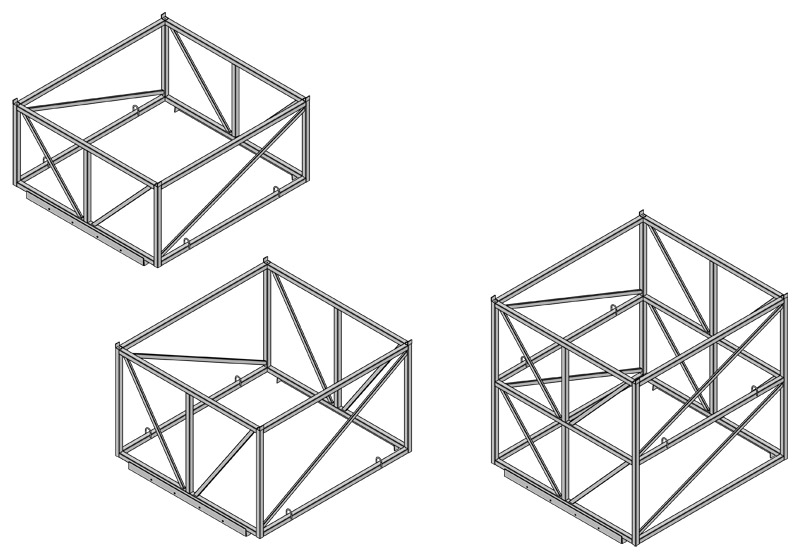

- Assembled form components of the VARIFLEX system.

- 4 standard formats: 2.50 x 4.00 m / 2.50 x 5.00 m/ 2.00 x 4.00 m / 2.00 x 5.00 m.

- Maximum slab height up to 6.00 m.

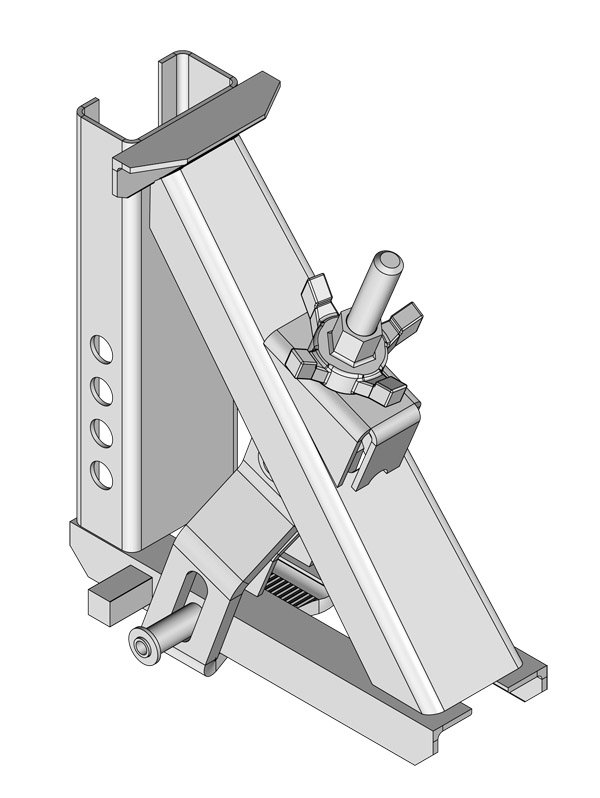

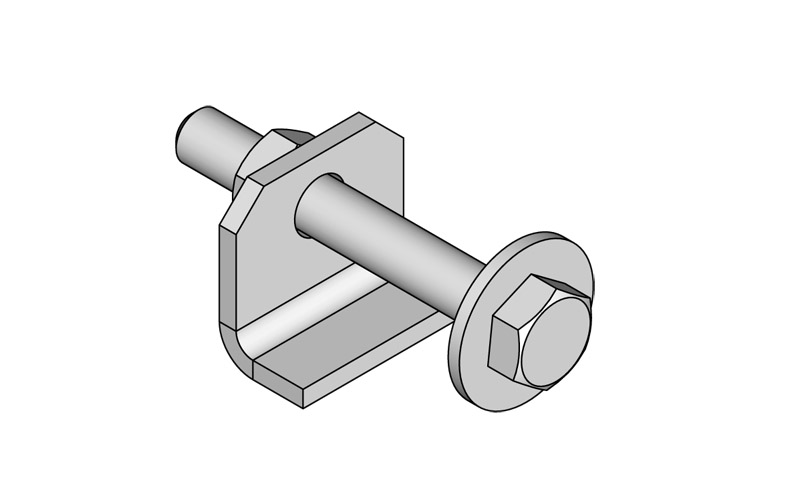

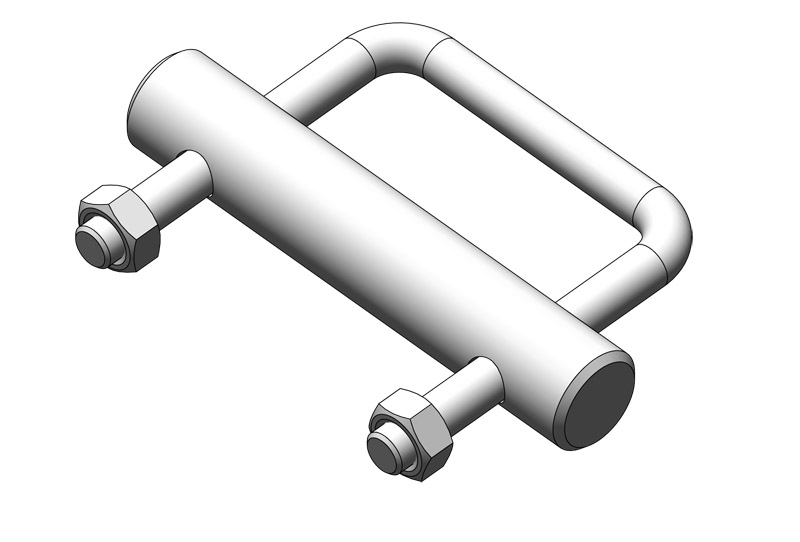

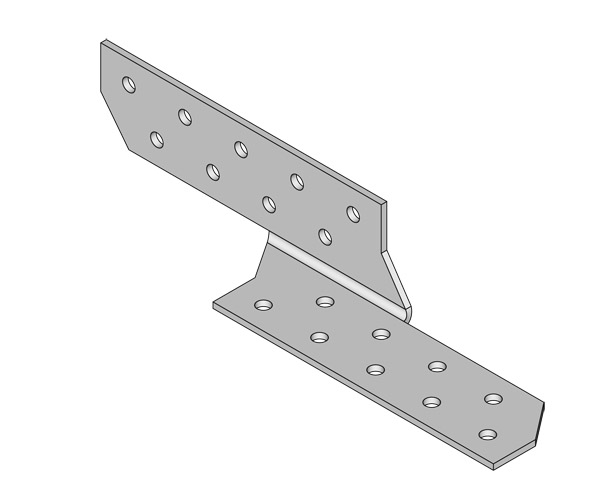

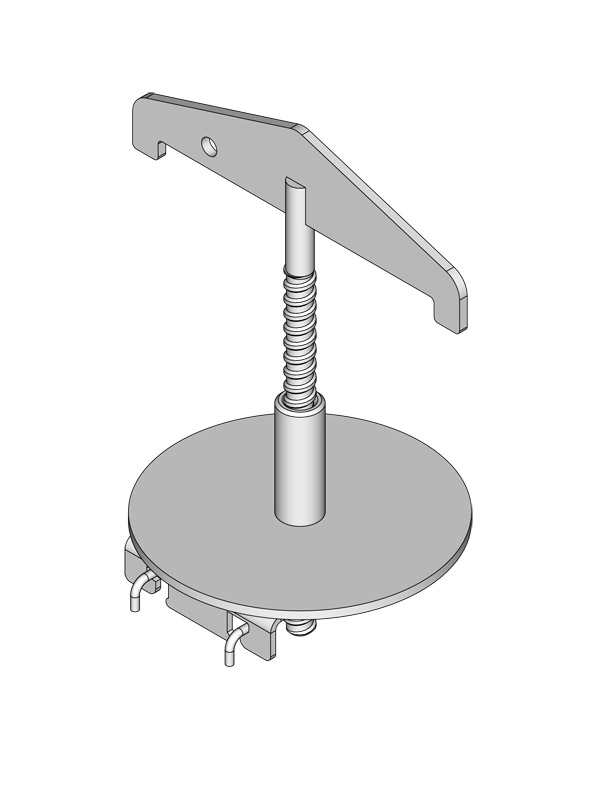

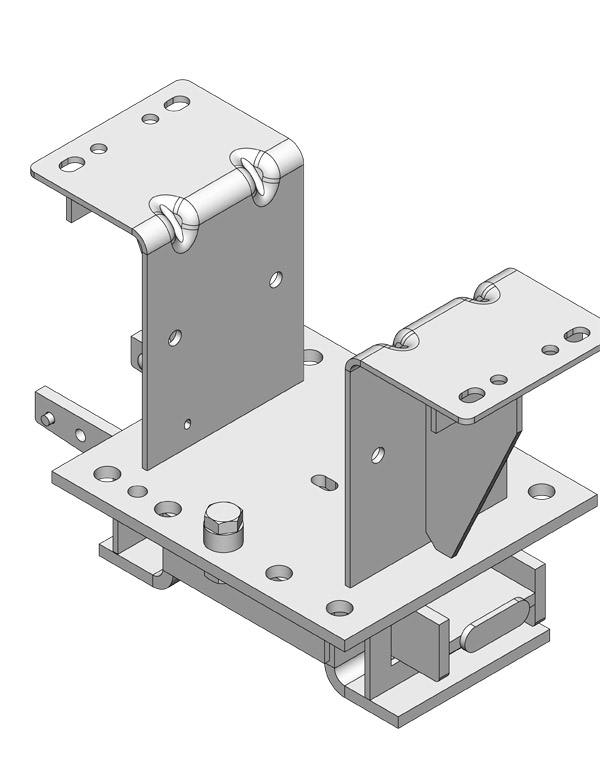

- Wedge-lock of the table head makes it easy to attach and detach props.

- Pre-assembled table grille for facing with any desired form-ply.

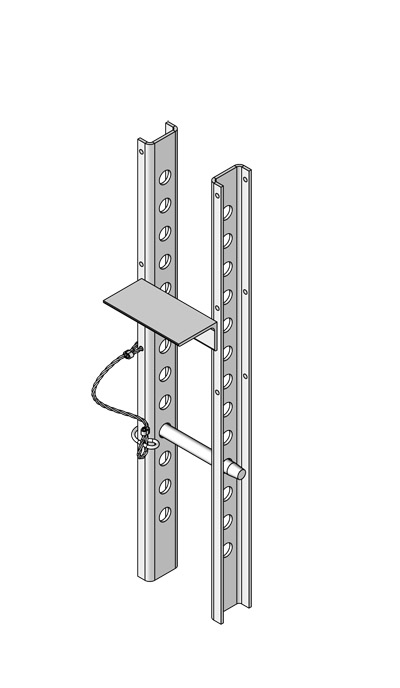

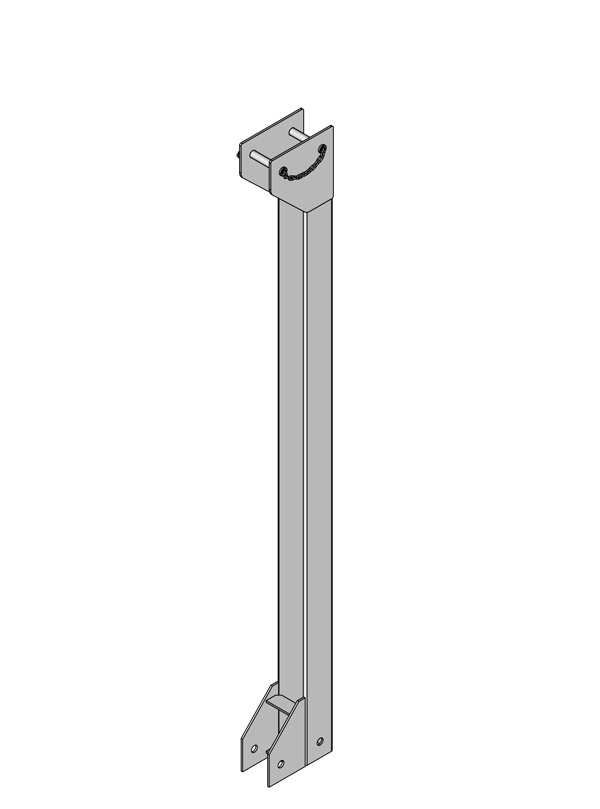

Fitting intermediate props

Intermediate props are mainly required where the tables have to be adapted for greater slab thickness (increased slab loads). The main props of the table (at least 4 of them must always be attached with a table head).